BEKA-FoodLine

Central Dry Belt Lubrication

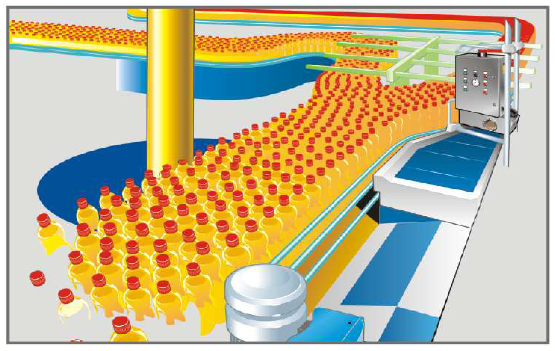

Food Packing and Processing

Machines in the food and beverage packaging and production industries across the globe have greatly benefited from BekaWorld lubrication systmes.

The economic and environment-friendly alternative.

Conveyor belts in the beverage bottling and food packaging industry are traditionally lubricated with soap and water. This procedure has decisive disadvantages, like enormous water consumption, massive foam load, corrosion, and hygenic problems. If there is not enough lubrication, damage of the card board boxes can occur due to high frictional force.

FoodLine stops all these problems!

Instead of spraying an enormous quantity of water, the FoodLine dry belt lubrication system applies an extremely fine film of dry belt lubrication agent onto the belts.

The lubrication intervals adjustment depends on use and capacity of the system.

The lubrication intervals adjustment depends on use and capacity of the system.

BEKA-FoodLine provides an efficient lubrication, which preserves the material being conveyed as well as the conveyor itself.

Advantages of this innovative technology:

- Eliminates enormous water consumption

- Reduces disposal costs

- Drier floors mean better work safety

- Saves packaging

- Reduction of micro biology

- Virtually eliminates corrosion problems

- Reduction of the annual operating costs

- Increase of efficiency

- No unhealthy aerosoles

BEKA-FoodLine offers lubrication solution from small stand-alone machines up to complete filling lines.

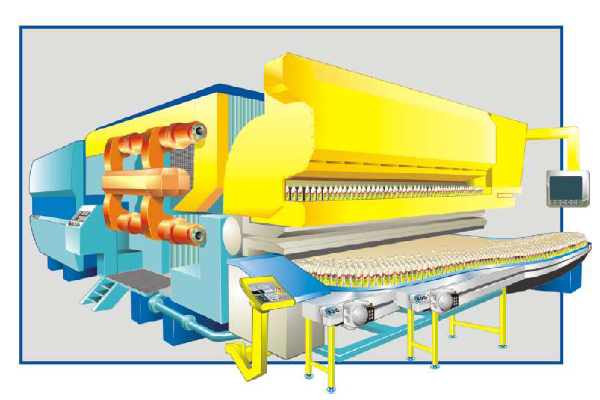

The system consists of the following components: pump unit, distributor strips, metering valves and applying brushes.

Work and break times of the systems can be adjusted with the electronic control. Together with external signals, different lubricants cycles can be controlled.

BEKA-FoodLine maintenance systems supply all machines in the filling and packaging industry with lubricant. Belt conveyors, fillers, packaging machines, labeling and washing machines periodically need fresh lubricant to guarantee the necessary performance and operational reliability.

Supply of single lubrication points

- Perfect for small numbers of lube points

- Simple and economical solution

- No need for external power or control

Solutions for stand alone machines

- Single line systems

- Multi line systems

- Progressive systems

The dual line system

- Used two or more of the stand alone systems

- Suitable for long distances

- Supplies the whole line with one pump

The Sectional system

- Flexible and extendable systems

- Optional monitoring of lube points

- Can be controlled by a PLC

Technology, you can rely on.