BEKA-FluiLub

Central Lubrication Systems for Light Rail, Heavy Rail, DMU, and EMU

- Cost reduction by wear reduction

- Reduction of curve noise

- Low installation expenses

- Low life cycle costs

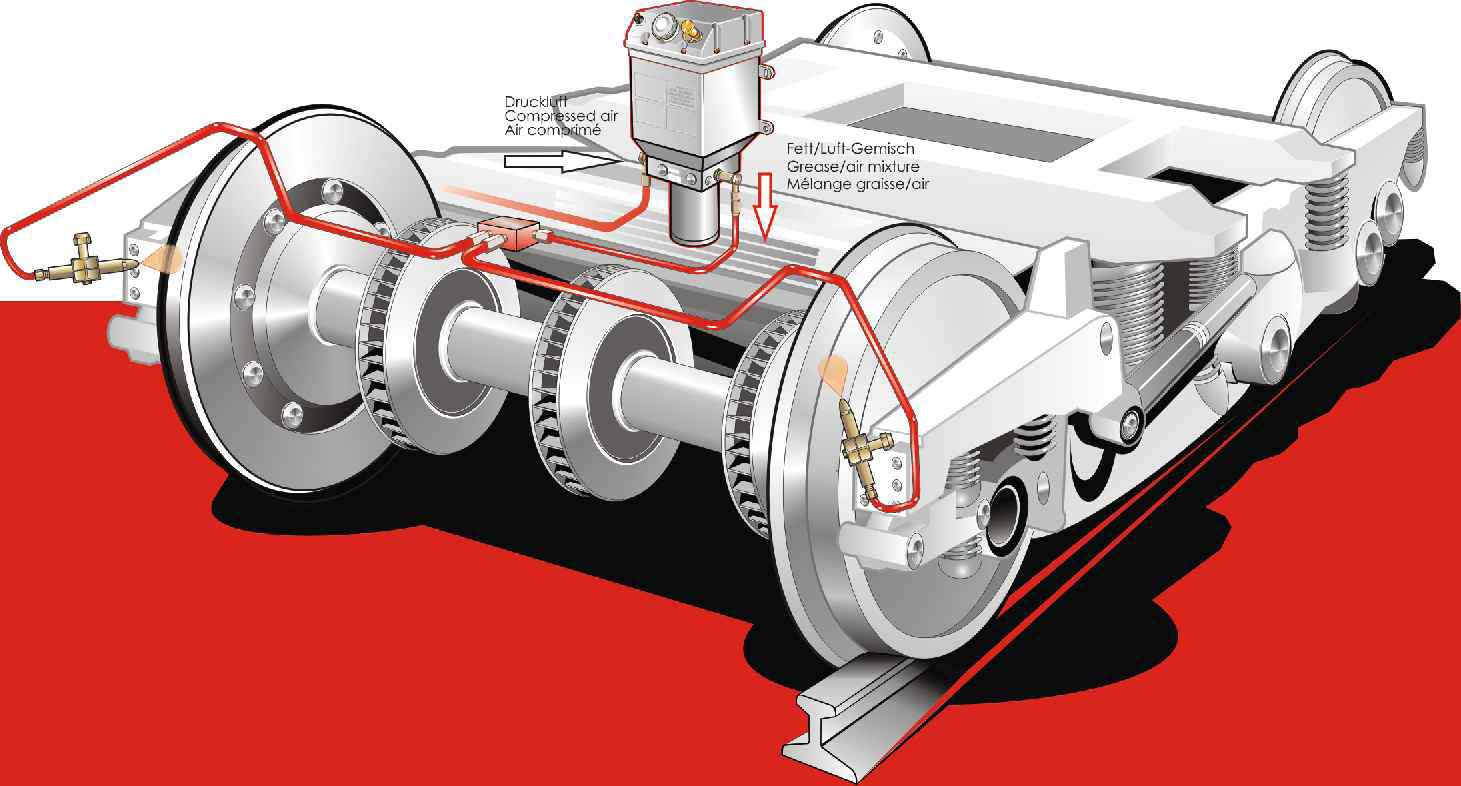

FluiLub wheel flange lubrication systems reduce wear on rail and wheel as well as reduce the noise in curves in a very efficient way. Innovative technology with tried-and-tested components and best cost to benefit ratio.

The FluiLub Pump

Extremely rugged pneumatic pump with welded aluminium or plastic container.

- Visual Level Monitoring Container

- Optional Electronic Monitoring

- Steady Mixing of the Lubricant

- Variable Delivery Rate

The FluiLub Mixing Distributor

The patented splitting insert of the FluiLub mixing distributor divides the lubricant splitting it up in to tiny droplets and distributes them like a drizzle to the airstream. This principle guarantees a homogeneous mixing ratio even with several spray nozzles.

The FluiLub Procedure

Compressed air transports the lubricant along the interior tube walls to the lube points. The special mixing distributors divide the lubricant precisely. One valve regulates the function of the pump and the other regulates the spray of air. In curves, both valves are actuated and the lubricant is applied onto the rail during the whole passing of the curve. The braking distance fulfills the guidelines of BoStrab. The FluiLub procedure reduces curve noise and wear of the rails in a very efficient way.